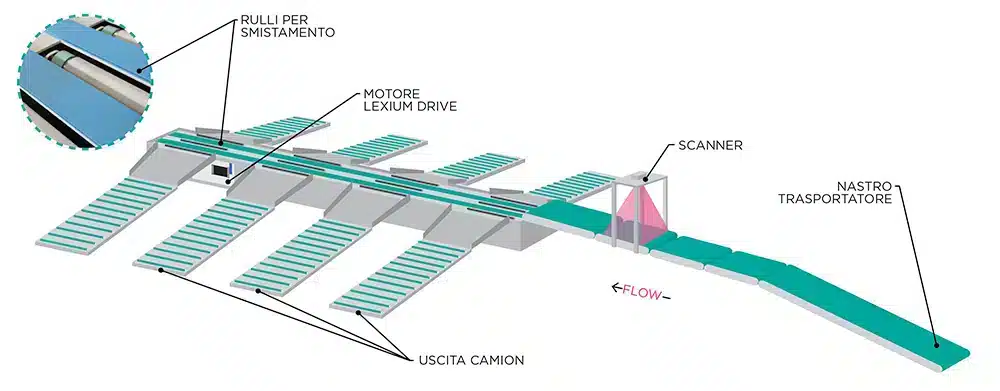

The application for sorting parcels has a fully automated operation. The postal package, equipped with a bar code, is identified at the line input and recorded: […]

The application for sorting parcels has a fully automated operation. The postal package, equipped with a bar code, is identified at the line input and recorded: the PLC knows the position in which it should be expelled. Consequently the parcel moves forward until it reaches the correct location by means of a set of rubber rollers rotated clockwise or anti-clockwise by the step motor, it is sorted into the left or right location.

All machine movements are effected via the stepper motors with integrated electronics from the Schneider electric motor Lexium range.

The electronics mounted on the motor enable the 104 engines which equip the line to interface with a single PLC by means of the Ethernet/IP communication protocol and costs, machine preparation times and the possibility of errors are considerably reduced by eliminating the wiring between the motor and drive system.

The Hybrid technology (closed loop drive system) that accompanies the Schneider Electric Motion motors guarantees maximum energy efficiency since the motors are activated only when necessary and, at the same time, it also prevents the motor stalling even with heavier parcels (up to 30 kg). The rated torque of 6.5 Nm means the use of a mechanical reduction unit is not required, thus greatly increasing the reliability of the machine and reducing maintenance to a minimum.

These measures mean the Risetec machine is capable of sorting up to 6,000 parcels per hour, compared to the 3000 of the previous version equipped with common gearmotors.