Introduction In the contemporary era, technological advancements have opened up new frontiers in video transmission, particularly in industrial contexts where image clarity and transmission continuity are […]

Introduction

In the contemporary era, technological advancements have opened up new frontiers in video transmission, particularly in industrial contexts where image clarity and transmission continuity are essential for efficient and safe operations. High- resolution videos offer detailed images that play a crucial role in quality control, surveillance, and process management in sectors such as Oil & Gas and advanced manufacturing. But how can we transmit this high volume of data on a platform that must rotate continuously? At the heart of this technological evolution lies the Slip Ring, an electromechanical device that facilitates uninterrupted transmission of electrical signals and data between fixed and rotating components of a system, eliminating issues associated with cable twisting. In industrial environments, Slip Rings play a crucial role in supporting advanced vision systems for process control and quality assurance, as well as in robust surveillance infrastructures needed to monitor and ensure safety at high-risk sites. This article aims to delve deeply into high-resolution video transmission via Slip Rings, outlining key technologies, tangible benefits, practical applications, and fundamental technical considerations for achieving optimal video transmission. Through a thorough examination, we will highlight the importance and potential of video transmission via Slip Rings in the modern industrial ecosystem, laying the groundwork for a comprehensive understanding of how this technology is shaping the future of visualization and data management in industrial settings.

Technology

The evolution of Slip Ring technology has led to the creation of high-bandwidth and high-speed models, capable of meeting the growing data transmission needs of high-resolution video systems. These technological advancements not only facilitate the transmission of high-resolution video but also pave the way for new possibilities, such as simultaneous transmission of multiple video channels, real- time control, and video data analysis, key elements for effective monitoring and management of industrial processes.

So, what are the characteristics and challenges that industrial Slip Ring manufacturers must address in this context?

Materials: The choice of materials is crucial for high-frequency transmission. Firstly, the cable selection is essential to ensure transmission performance, especially in industrial environments where, in addition to electrical and shielding characteristics, it is important to consider environmental conditions such as the presence of oils or other aggressive chemicals, and mechanical peculiarities useful during machine

assembly and setup. The second aspect to consider is the choice of materials for brushes and rings. Although silver alloys offer high conductivity, preference often leans towards gold alloy due to its oxidation resistance, which ensures stability of electrical performance over time.

Design: The choice of Slip Ring design is as important as material selection. In this case, it is advisable to rely on professionals capable of analyzing the surrounding conditions of the application and balancing dimensional requirements with performance and disturbance rejection needs. The Slip Ring structure does not allow for the entire transmission channel to be shielded from disturbances, and paradoxically, the rings themselves can cause interference. However, there are several measures that can be adopted to minimize these effects, such as bringing the cable shielding close to the brushes or implementing impedance matching.

Environment: In this scenario, it is crucial to enlist the support of specialized technicians who can advise on the best configuration within the machine to ensure desired performance and mitigate any external factors, based on experience gained in collaboration with the customer.

Advantages

High-resolution video transmission via Slip Rings offers a range of distinct advantages, particularly in industrial settings. Some of the key benefits include:

Efficient Transmission:

Ability to transmit one or more uncompressed high-quality videos (e.g., standard and infrared) with a bandwidth of up to 10Gb/s between fixed and rotating parts of the system seamlessly.

Plug-and-Play Connectivity:

The presence of RJ45 or M12 connectors provides standardization that facilitates direct plug-and-play connectivity, simplifying installation and maintenance.

High-Performance Contact Technology:

Advanced contact technology ensures stable signal transmission, minimizing packet loss (BER), and ensuring reliable connection even in demanding industrial environments.

Reliability and Durability:

Slip Rings are less prone to wear and deterioration compared to cables, thanks to their ability to transfer power and signals without fixed or elastic connections between stationary and rotating structures.

Versatility and Channel Combinations:

With multiple combinations of Ethernet channels, power, and signal, Slip Rings offer versatility that supports a wide range of industrial applications, such as vision systems and professional surveillance cameras.

Elimination of Cable Twisting:

Slip Rings provide an effective solution to prevent cable twisting and tangling during continuous system or machine rotations, facilitating cable management, reducing downtime, maintenance, and increasing productivity.

Advantages

High-resolution video transmission via Slip Rings offers a range of distinct advantages, particularly in industrial settings. Some of the key benefits include:

Efficient Transmission:

Ability to transmit one or more uncompressed high-quality videos (e.g., standard and infrared) with a bandwidth of up to 10Gb/s between fixed and rotating parts of the system seamlessly.

Plug-and-Play Connectivity:

The presence of RJ45 or M12 connectors provides standardization that facilitates direct plug-and-play connectivity, simplifying installation and maintenance.

High-Performance Contact Technology:

Advanced contact technology ensures stable signal transmission, minimizing packet loss (BER), and ensuring reliable connection even in demanding industrial environments.

Reliability and Durability:

Slip Rings are less prone to wear and deterioration compared to cables, thanks to their ability to transfer power and signals without fixed or elastic connections between stationary and rotating structures.

Versatility and Channel Combinations:

With multiple combinations of Ethernet channels, power, and signal, Slip Rings offer versatility that supports a wide range of industrial applications, such as vision systems and professional surveillance cameras.

Elimination of Cable Twisting:

Slip Rings provide an effective solution to prevent cable twisting and tangling during continuous system or machine rotations, facilitating cable management, reducing downtime, maintenance, and increasing productivity.

Applications

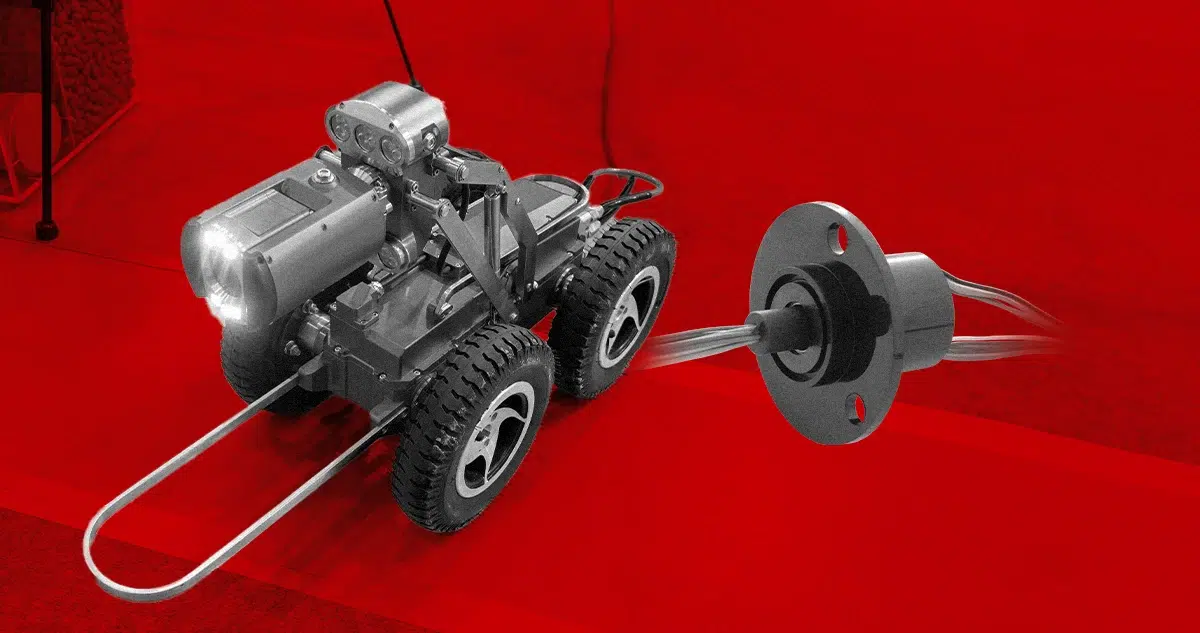

As previously mentioned, among the main applications requiring high-resolution video transmission and therefore considerable bandwidth are remote surveillance systems in critical environments such as the oil & gas sector or territorial control, where monitoring vast areas is necessary. High resolution allows avoiding the use of complex and expensive optics thanks to digital zoom, and identifying critical events even at great distances. Slip Rings contribute to cost reduction by minimizing the need for advanced optics and decreasing the number of cameras thanks to the ability to move a single camera to cover a larger area.

In the industrial sector, a rapidly growing area involves vision systems, which, supported by artificial intelligence software, are capable of learning, identifying production defects, and adjusting machine operations based on the output produced. A significant example is represented by pipe welding applications: the high image resolution allows analyzing the quality of welding across the diameter of the pipe. Thanks to Slip Rings, welding quality can be significantly improved, reducing risks in critical applications. Similarly, in aesthetic inspection of paintings or other critical treatments, the use of robots equipped with cameras capable of inspecting complex components, such as those in the automotive sector, greatly benefits from high-resolution video transmission via Slip Rings.

Comparison with Other Technologies

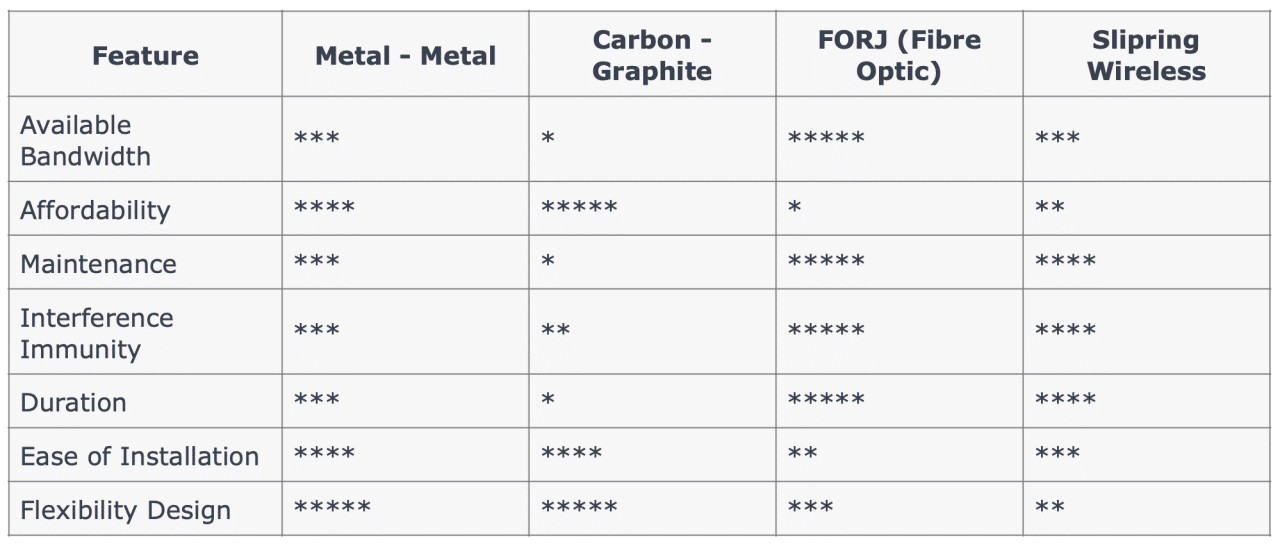

What other transmission technologies, besides the metal-to-metal one examined in this article, are available on the market and can meet the needs of high-resolution video signal transmission?

Carbon-Graphite Contacts: These are not typically used for high-frequency transmissions because the variation in electrical characteristics over time does not guarantee consistent operation. This forces users to perform continuous maintenance, having to clean the tracks due to the high dust generation caused by the wear of the pads.

Fiber Optic Rotary Joints (FORJs): They are certainly the most technically advanced solution for transmitting high-frequency signals of any nature. Potentially, a fiber optic joint has nearly infinite bandwidth. However, it is important to consider the need to apply a pair of copper-optical converters or a pair of MUX/DEMUX to transmit multiple signals over a single channel. Typically, the conversion electronics determine the usable bandwidth limit. The costs of these solutions are high compared to metal-to-metal technology. Servotecnica is capable of integrating these solutions into metal-to-metal joints and developing the related MUX/DEMUX electronics for applications where compromises cannot be accepted.

Wireless Slip Rings: Typically based on inductive technology, they lend themselves to transmission up to bands of 1Gb/s. They have a high cost and usually offer poor customization options, not lending themselves well to modifications. Compared to a FORJ, they have the advantage of being able to have a through-hole.

Conclusion

The growing demand for high-resolution video transmissions in industrial settings has led to the evolution of various transmission technologies. Among these, metal- to-metal Slip Rings emerge as a reliable and relatively economical solution to facilitate continuous data transmission between fixed and rotating parts of a system. The analysis presented in this article has highlighted how Slip Rings offer a range of tangible benefits, including efficient transmission, plug-and-play connectivity, reliability, and durability, as well as versatility in terms of channel combinations. These features make Slip Rings a preferred choice for critical industrial applications, such as advanced surveillance and vision systems.

The comparison with other transmission technologies has further outlined the strengths of metal-to-metal Slip Rings, especially when compared to alternatives such as carbon-graphite contacts, fiber optic rotary joints (FORJs), and wireless Slip Rings. Each technology has its own peculiarities and ideal application scope, but metal-to-metal Slip Rings offer an effective balance of cost, performance, and ease of maintenance, making them a solid choice for many industrial applications.

In summary, high-resolution video transmission via Slip Rings represents a key component for supporting efficient and safe operations in numerous industrial sectors. This article has provided an in-depth analysis of how Slip Rings facilitate high-resolution video transmission, highlighting their increasing importance in the modern industrial ecosystem and providing a useful overview for those interested in exploring the potential of this emerging technology.